- Ease in modification of logic

- reduced size

- For fully automated processes

- Include PLC, HMI and automation components

INSTRUMENTATION CONTROL PANELS

Instrumentation Control Panels

The final controlling device can be a suitably rated electromechanical contactor or solid state relays for single and three phase load. A wide variety of industries including: petrochemical, refineries, pipelines, pharmaceutical, water wastewater, and food processing.

PLC Automation Panels

Programmable logic controller (PLC) control panels or also known as PLC Automation Panel are one of the most important and efficient kinds of control panels. Which are generally used in variety of electronic and electrical circuit fittings. PLC Control Panels we manufacture are highly capable of giving higher output at less power consumption. Integrated with solid PLC logic and flawless PLC hardware programming. Ease in modification of logic, reduced size, means of remote communications and advances in the technology have made PLC Automation Control Panels an edge over conventional relay based systems. Control Systems Engineers has provided PLC based Panels from PLC of Allen Bradley, Siemens, Modicon, GE Fanuc. From small I/O application to the complex I/O systems are provided by the Control Systems Engineers. Control Systems Engineers have developed communication software's for remote communication of the PLC Panels in various different protocols. With PLC based Panels HMI/MMI are provided to provide the operator various messages and controls of the process plants touch screen MMI are provided. To effective control of the system.

PLC Automation Panels

Process Industries Batch manufacturing Industries Continous Process Industries Chemical, Cement, Food and Pharma

vfd Panel

The VFD Panel (Variable Frequency drive panel) also known as VFD Control Panel are designed to control the speed of electric motor and feed pump. They are widely used in drilling, pumping and other large machine applications. The VFD panels are widely used in extruder plants, rolling Mills, tube mills, paper mills, cable industry and CTL Lines. Adjustment of the speed of the motor is the application, which is required in all the process industries & machinery Mfg.'s. Variable Frequency drive is used as energy saving device for some of the machines to save power during no load or it is used as final control element of the closed loop control application where the speed of the motor is changed to control one parameter. Some of the application is provided with manual speed control of the motors. These are the open loop control applications.

vfd Panel

- Adjustable speed

- Adjusting speed of different motors according t process

- Easy to use

- Operater friendly

Batch process manufacturing Continous process industries Controlling blowers and fans

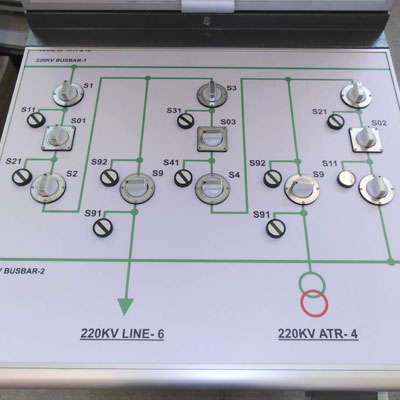

Mimic Panel

In order to provide clarity of the process with the operation of the equipment Mimic Panels are provided. Mimics are made in vinyl/polycarbonate with LED's. Special electronic circuits are developed by Control Systems Engineers to show the flow of the raw material/product. On the MMI screen dynamic mimic is provided with all the relevant process informations. This makes the operator user-friendly access. Even though PCs are widely used for viewing of the processes, there is still no substitute to mimic panels which are also called as mimic display panels. In mimic display or mimic panels the process or flow charts are pictorially represented on the front panel of the Control desk. Generally nowdays they are printed on polyester or polycarbonate sheets and provided with acrylic front sheet for protection. Super bright LEDs with viewing distance of 100 meters are used in the MIMIC PANELS also equipments are mounted on the MIMIC Display. Mimic panel is a fire and gas purpose panel on which shows a geographical layout of the installation and equipment to represent rapid visual appraisal of any fire and gas hazard. Mimic panel shall be installed at convience location to the personnel sight. Mimic panel for building should be installed somewhere near building entrance. Mimic panel shall be furnished with indicator/lamp to indicate the existence of fire or gas leak and pushbutton/switches to do plant shutdown or extinghuisant system manual activation. The panel should also provide indication of fire and gas equipment status such as fire water pumps, foam system, etc. Critical push button shall have guard/protection such as flap or cover to avoid accidental operation. The following picture shows example of mimic panel. The alternative construction for mimic panel is tile matrix which allows easy modification for additional or removal items by changing the tile.MIMIC is the representation of any process plant for which is displayed on the Panel or Control Desk. This representation makes it easy to monitor the whole plant from one location and is also used as a second level backup.

Mimic Panel

- Easy installation

- Top class quality

- Long functional lifeModular Structure

- User Friendly

- Perfect Finish

- Durable

- Abrasion Resistant

- Highly Effective

- Outstanding in Quality

MIMIC is the representation of any process plant for which is displayed on the Panel or Control Desk. This representation makes it easy to monitor the whole plant from one location and is also used as a second level backup.

Monitor Panel

Monitor panels are used to monitor different process parameters. Monitro panels are used in continous process monitoring industries.

Monitor Panel

- Monitor process parameters

- Continously monitor analog process parameters

Continous monitoring chemical industries Fertilizer Industries

Electrical Panel

In mimic display or mimic panels the process or flow charts are pictorially represented on the front panel of the Control desk. Generally nowdays they are printed on polyester or polycarbonate sheets and provided with acrylic front sheet for protection. Super bright LEDs with viewing distance of 100 meters are used in the MIMIC PANELS also equipments are mounted on the MIMIC Display. Mimic panel is a fire and gas purpose panel on which shows a geographical layout of the installation and equipment to represent rapid visual appraisal of any fire and gas hazard. Mimic panel shall be installed at convience location to the personnel sight. Mimic panel for building should be installed somewhere near building entrance. Mimic panel shall be furnished with indicator/lamp to indicate the existence of fire or gas leak and pushbutton/switches to do plant shutdown or extinghuisant system manual activation. The panel should also provide indication of fire and gas equipment status such as fire water pumps, foam system, etc. Critical push button shall have guard/protection such as flap or cover to avoid accidental operation. The following picture shows example of mimic panel. The alternative construction for mimic panel is tile matrix which allows easy modification for additional or removal items by changing the tile.MIMIC is the representation of any process plant for which is displayed on the Panel or Control Desk. This representation makes it easy to monitor the whole plant from one location and is also used as a second level backup.

Electrical Panel

- Easy to use

- One stop control for all electrical components

- low cost maintainance

- Operater friendly

Controlliing different electrical components in indsutries Rresidential as well as corporate buildings

Power Distribution Panel

An electrical panel is also called a load center. It is a metal electrical service box that accepts the main power to the home and distributes electrical current to the various circuits within the home. The distribution of power to the various circuits are protected from over-current by the use of circuit breakers or fuses. You will find the circuit breakers stacked in the panel and controlled with a lever that places it in the "On" or "Off" position. You will also see a double pole circuit breaker at the top of the panel called the "Main". That breaker controls all the power to panel in the circuit breakers. The main breaker is used to power all the circuits on or off at one time. At the main circuit breaker you can also see the amperage capacity of the electrical panel. The main breaker will have a number on it identifying its ampere capacity, for example, "100" or "150". Today, 100 amp service is the minimum allowed by code in residential construction so 150 amp is very common. Electrical panels also come in 200 amp and 400 amp configurations. To identify a circuit you should find stickers placed next to each breaker or a sheet adhered to the inside of the panel door that identifies the circuit served by a particular fuse or circuit breaker.

Power Distribution Panel

- Redundant Power Inputs

- SNMP Support

- Alarm Monitoring Option

- Industrial-Grade Durability

Industrial Applications Domestic Applications Commercial application

Apfc Panel

APFC or Automatic Power Factor Control Panels are mainly used for the improvement of Power Factor. Power Factor can be explained as ratio of active power to apparent power and it is a key factor in measuring electrical consumption. Everyone knows that how costly electricity has become in present time. Therefore it becomes utmost important to cut down on electrical consumption for reducing expenditure. M

APFC Panels come real handy in the achievement of this purpose Use of these control panels becomes indispensable in those industries where electrical installations are meant to supply to large electrical load. A dip in Power Factor can attract operational losses and a penalty from electricity board, responsible for electricity supply. APFC Panels can effectively and automatically manage quickly changing and scattered loads along with the retention of high Power Factor. We are renowned manufacturers of APFC Panels symbolized with quality and reliability. These are available in different current ratings to cater to distinct applications.

Apfc Panel

- Fast Real Time Transient-Free switching of Capacitor Banks

- Prevents damage to sensitive electronic equipment in notwork

- Highly intelligent micro processor based 3 phase P.F. Controller with Dual P.F. Setting and Master Slave modes

- LCD Controller has inbuilt with Load Manager with front optical port

Refrigeration systems, e.g. in

- Construction and Engineering

- Data Center/Colocation/Hosting

- Education

- Fire/Alarm/Security

- Government

- Healthcare

Change Over Panel

Since years, we have been engaged in manufacturing and supplying an excellent stock of Change Over Panel. These panels enable automatic start up of the standby generator. In addition, it also ensures safe, fast transfer of the load in the event of a mains power cut. When mains power is restored, these panels automatically disconnect the generator and connect the load back to the mains. This Change Over Panel comes with an excellent benefit of an LCD, allowing the voltage and frequency parameters on both the mains and generator sides to be simultaneously displayed.

Change Over Panel

- Epoxy powder coating for corrosion protection

- Long working life

- Low maintenance cost

- Can be changed to generator mode automatically

- When EB supply resumes it goes back to EB mode

- Switches off the generator automatically

- Shock proof

- Durable

- Strong and sturdy

- Easy to operate and install

Construction Field Chemical Industries Packaging Industries Texturizing Industries Pharmaceuticals Industries Paint Industries Metal Industries Cement IndustriesOil Industries Power Transmission & Distribution Cable Industries, Plastic Industries

LT Panel

LT Panel is an electrical distribution board that receives power from generator or transformer and distributes the same to various electronic devices and distribution boards. Such panels are used in industries both for internal and external use and, therefore, they are quite rugged to withstand different climatic conditions. Our LT panels are designed to work with low electricity consumption that makes them cost effective. There are various uses of LT Control Panel as per the user requirement, the main being as Control Center or Feeder or Distribution Board. LT Control Panel receives the main power supply either from Generator or Transformer and distributes the same to various electronic devices and distribution boards. With the help of protective switch gears, they are used for controlling and monitoring the mains supply from a centralized location. There are various applications of LT Control Panel. Some of them are listed as Medium to High capacity Manufacturing Industry, Hospitals, Educational Institutions, Commercial Complexes, Hotels

LT Panel

- Hassle free Maintenance

- Highly efficient

- Specifically design, user friendly, dust & Vermin proof modules, Flush mounted meters to indicates line voltage & current.

- Provision of incomer cable form to bottom enables you to install the panel in existing panel room without the requirement of civil trenches.

Medium to High capacity Manufacturing Industry Hospitals Educational Institutions Commercial Complexes

MCC Panel

MCC stands for motor control center. It consists of feeders for motors and blowers. Feeders are designed according to the motor rating. In most of the MCCs, auto/manual provision will be there. With manual provision motors can be operated manually. In auto provision external signal is required to start the motor. The signal is given by the control panel. Indicators for the motor operation also will be present in control panel. A motor control center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starters. A motor control center can include variable frequency drives, programmable controllers, and metering and may also be the electrical service entrance for the building. In many commercial and industrial applications, quite a few electric motors are required, and it is often desirable to control some or all of the motors from a central location. The apparatus designed for this function is the motor control center (MCC).

MCC Panel

- Excellent performance

- Low cost of maintenance

- Impeccable finish

Chemical Plants Industries

ABS/ Polycarbonate Enclosure

The ABS Polycarbonate Enclosures are used where normal MS and SS Panels cannot be used. As a self-extinguishing material, polycarbonate requires no protective coating. ABS is another amorphous thermal plastic material with good physical properties and high resistance to chemical attack. It is an ideal cost effective material. ABS materials are less protective against UV rays if directly exposed. ABS/Polycarbonate enclosures are designed for indoor and outdoor use, but are small and light-weight, and provide a high tolerance to harsh environments. They come in multiple sizes and styles that fit small to mid-sized equipment.

ABS/ Polycarbonate Enclosure

- Easy machining with normal tools

- Easy colouring through pigmentation

- Low weight

- Good resistance to chemical attack

- Excellent insulating properties

Food Industries, Pharma Industries, Chemical Industries

Aluminum Enclosure

Aluminium enclosures are much lighter as compared to MS and SS Panels. They are light weight and durable.

Aluminum Enclosure

- Good resistance to chemical attack (painted)

- High impact resistance

- Wide operating temperature range

- Easy earthing

- Good heat sink properties

- Rigid construction

Hazardous areas Process industry Machinery Transportation Port facilities Packing industry