Project & Solution

Flow Control Station

Flow Control Stations (FCS) are specially designed terminal units to monitor and control large volumes of air in bothsupply and exhaust systems. Multiple configuration options allow you to build the optimal assembly for your application.Nuvision supply and exhaust flow control stations are an excellent way to reduce noise, save energy, andReduce operating costs. The FCS can be customized to suit your application as it is available in a widerange of sizes, to accommodate all airflows, with a variety of options. Typical production fluids are a mixture of oil, gas and produced water. Many permanent offshore platforms have full oil production facilities on board. Smaller platforms and subsea wells must export raw production fluid to the nearest production facility, which may be on a nearby offshore processing platform or an onshore terminal. Sometimes the produced oil may be stabilised (a form of partial distillation) which reduces vapour pressure and sweetens "sour" crude oil by removal of hydrogen sulphide, thereby making the crude oil safer for storage and transport.

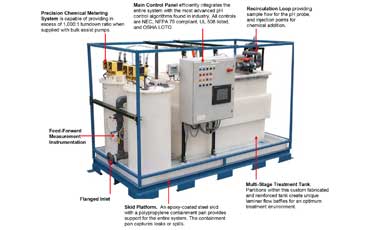

Dosing Control Station

Chemical dosing is the delivery of a chemical substance into foul water, sewage or sludgeŌĆōlike fluid, usually as part of preliminary processing. It is most often used on sewage treatment, as part of the anaerobic digestion process for making energy from waste and for cleaning industrial effluent to be returned to the natural water course. Here Philip Brown, Project Manager for pumping solutions at Verder UK, explains the process.The dosing process A chemical dosing skid is the most effective way to dispense chemicals, using at least two peristaltic or metering pumps attached to pipe maniflolds encased in a cabinet. One pump acts as a duty standby to ensure the dosing process is uninterrupted should a wearable component need to be serviced. A chemical dosing system uses pumps to automatically control the dosing process. In the case of wastewater treatment works, there are certain environmental regulations in place from the water regulator, so when sewage enters the works, the effluent has to be filtered, cleaned and processed.

Tank Level Control Station

Tank Level Control Station-a global market leader in pressure, temperature and level measurement technology. Working together with you, we develop comprehensive solutions based on our high-quality measurement technology components, with the solutions ultimately being integrated into your business processes. Also in the field of level measurement, individual requirements demand tailored solutions: Whether particularly large or highly precise ŌĆō level measurement is our passion. We offer a wide range of level measuring instruments for temperatures up to 450 ┬░C or pressure ranges up to 400 bar. A major part of the development is applied to individual solutions for the widest variety of applications in the chemical, pharmaceutical, offshore and petroleum, shipbuilding and food industries, as well as for machine building and plant construction, water treatment plants and increasingly more often for the extensive environmental engineering sector. Our qualified employees are always dedicated to finding the solution to customer-specific problems. The latest production techniques, uncompromising quality management as well as national and international approvals are further prerequisites for our company's good name.

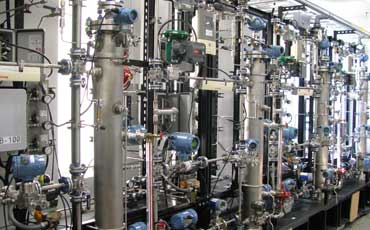

Gas Mixing Station

Mixed Gas Skids are used in steel plants to mix different gases like Blast Furnace Gas, Coke Oven Gas, Converter Gas, Propane Gas in desired proportion as required by the Furnace Burner. The design should deliver the required homogeneously mixed gas at desired calorific value at the outlet of the skid with minimum pressure drop across the skid .The control and instrumentation system provides a complete Piping Skid ready to use at site . We do design, engineering , fabrication, supply and commissioning of the Mixed Gas skids to deliver the desired results. Mixed Gas skids comprises of pressure control and flow control loops, Spurger arrangement to improve homogeneity with less pressure drop. A calorific value analyzer, which monitors the outlet mixed gas calorific value on real time basis and correct the flow rate to get the desired value without compromising the flow rate. The system provides safety interlocks, audio-visual alarms. The system can be designed either with conventional controller based or with PLC/ SCADA system. The system provides features like data acquisition, alarm management, report etc.

Oxygen Measuring Station

Oxygen is one of the very important elements which is not only used in various industrial applications but also are used for several laboratory purposes. Our company understands the needs and requirements for the installations and use of this oxygen gas widely on large scale and hence has brought forth one of the finest quality Oxygen Flow Skid in the market. These skids provides the facility to efficiently connect the oxygen cylinders together and provide a convenient and comfortable means of handling them in most appropriate manner. We offer Oxygen Gas Flow Skid, which is fabricated using quality tested raw material. Available in varied specification, these can be customized as per the specification of clients. The Oxygen Gas Flow Skid is designed for a long trouble free life, at the same time carrying aesthetic appeal, with its elegant appearance. The body of the Oxygen Gas Flow Skid is brass plated with chrome. This makes it rugged and attractive.'

Water Analisys Station

The monitoring of watercourses and coastal areas requires continuous monitoring of the quality of water in the natural environment and industrial discharges. NUVISION offers tailor-made water quality analysis stations, adapted to all types of environment, to measure and monitor in real time the quality of the water in natural environment, in retention basin and on industrial sites.The AquaStation independent monitoring station is a breakthrough in remote water quality monitoring. The AquaStation is able to independently collect data, keep its sensors clear of fouling and calibrate its sensors remotely via itŌĆÖs built in telemetry system.

- Self contained and self powered (solar / wind)

- Self-calibrating

- Self cleaning

- User configurable sampling times, cleaning intensity and calibration frequency

- Analysis results viewable 24/7 on line from any location

- Low maintenance

- Various sample pump options to suit all applications

- Various telemetry options

- Configurable alarms with user-specified set points generate Email or SMS alerts

- Live data available on site with built-in Aquameter

- Measurement of up to 16 individual parameters simultaneously

- Secure, weatherproof, lockable enclosure

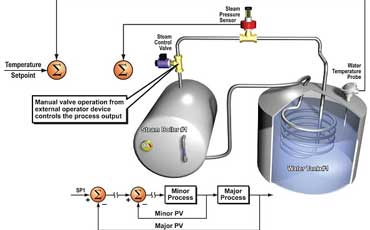

Temperature Control Station

Temperature Control Station-customer-specific solutions are a key element of the electrical temperature measurement product range. These thermometers are developed, manufactured and tested individually for your applications. Whether you are talking about the detection of complex and safety-relevant temperature profiles in reactors or the monitoring of the critical pipe temperatures in furnaces and combustion chambers ŌĆō WIKA has a tailor-made solution ready for you. In other market segments too, such as in plastics manufacturing (LDPE) at pressures up to 3,000 bar or in processes in sanitary applications, you can also rely on our experience.

Pressure Control Station

Pressure Control Station-Your requirement - our solution

Many industrial plants produce high-pressure steam for process work. In many of these plants, there is excess steam capacity available that can be utilized for other purposes, such as space heating, water heating, etc. Process steam is often generated at a higher pressure than can be used for the other purposes. Whatever the needs for lower pressure steam, a pressure reducing station will be required. A pressure reducing station is more than just a reducing valve fed off a steam main. A properly designed and installed pressure reducing station takes into consideration velocity, good piping practices, and safety.

PH Control Station

Systems for pH control are characterized by extreme rangeability and sensitivity, and are also subject to difficulties arising from contact between measuring electrodes and hostile fluids. Case histories of representative installations show that success in implementing these control systems depends not only on assessing the complexity of the loop and selecting a control strategy but also on recognizing and avoiding pitfalls while specifying and installing instrumentation, equipment and piping.

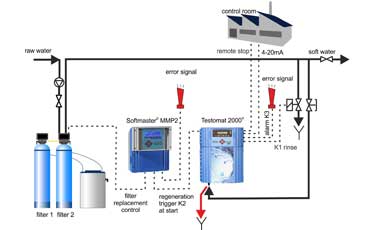

Hardness Control Station

For automatic control of the water hardness for larger systems often a self-controlled water hardness monitoring unit is used. Thus, the steam system is always perfectly protected against too hard water. Alternatively, manual water test kits can be used, which require a continuous measurement of the water quality by the operator.

Paper Plant Projects

Nuvision has developed the process measurement & control product line-up with the collaboration with pulp & paper industry based on the process knowhow and experiences. NuvisionŌĆÖs wide and powerful sensors line-up are available with ''best-fit-model selection'' for every process in the pulp & paper plant, and delivers stability, precision, robustness in process measurement even under the challenging application such as digester and washer in chemical pulp plant. The high performance and intelligent controller helps to achieve higher quality production control in the pulp and paper.

Chemicals Plant Projects

For capital projects in the chemical or petrochemical industry you may be challenged to mitigate risks, maintain the project time line and stay within budget. All of which can be carefully managed and supported by an embedded engineer who has extensive instrumentation know-how and who works closely with the engineering team. That is one solution to effectively drive capital projects to success. Nuvision always provide and accept challenges to complete/execute Petrochemicals and Chemicals industries projects.

Petro Chemicals Plant Projects

We build a variety of custom process systems to meet your needs. Typical types of systems are listed below, but we work with many process technologies to build pilot plants, demonstration plants and full sized commercial plants. Distillation columns Solvent recovery rystems Absorption systems Continuous mixing systems Batch mixing and blending systems Batch reactor systems Utility and raw material handling systems Pipe bridges Heat tracing Desalting systems Emulsion systems

Extraction Unit Control Station

From dust extractors to unit control station to hall ventilation systems, We provide the best service to your specialist in the area of extraction technology. We supplay a wide range of innovative dust extractors and extraction systems with a wide range of filter technologies and tailor-made extraction solutions for industry.

Punematic Skid Testing Station

Nuvision, the leading supplier of automation solutions for filtration skid manufacturers ... air supply. Control cabinet boundary. Butterfly valve with pneumatic actuator.

Flame Proof station

Nuvision offers a wide variety of Flameproof Panel and other accessories. We employ trained and experienced staff, possess advanced infrastructural facilities and innovative strategies to devise first-rate products that suit customersŌĆÖ requirements. Our Flameproof items are used in different areas for Instrumentation, Controller ,Indicators and panel the surroundings in various industries, warehouses, Industrial buildings and more. With us, you can be assured about excellent quality, durability and low prices.

Reactor Control Panel

We are highly appreciated in the market for our exquisite collection of Reactor Vessel Heating Control Panels. All these control panels are manufactured keeping in consideration the variegated requirements of our respectable patrons. Our product-line is available in a spectrum of sizes and models at most competitive prices.

Vibration Monitoring Division

Abnormal vibrations are often the first indication of a potential machine failure. Conditions that can cause these vibrations include unbalance, misalignment, looseness of parts, deteriorating rolling element bearing and gear damage. Vibration analysis instruments and systems can help detect many serious problems at an early stage, allowing personnel to undertake remedial work in a timely manner. We will work with you to help ensure that your asset condition monitoring system is there when you need it. When there is a problem, we can perform diagnostics and give you advice on the cause and how to fix it. We can provide this service, quarterly, monthly or on-demand.

Steel Plant Projects

We provide the Steel Industry projects that include the detailed information of the latest technologies or updates in the industry. We are provide below solutions to steel industries. Field Instrumentation: Engineering, procurement, installation, commissioning and performance trials - Core strength in process automation Control System: Engineering, supply, installation & commissioning on turnkey basis - Single window solution for the user Data Acquisition: Acquisition, logging & reporting - Recipe management and statistical analysis, Optimization of process & resources Remote Networking: From simplest serial communication to ethernet, fiber optics, dial-up, web & wireless - Information; anywhere, anytime