- It is available in wide range.

- It has long life.

- It cost is low.

- Time tested application.

- Accuracy is high

PROCESS INSTRUMENTATION GAUGES

Process Instrumentation Gauges

Our pressure gauges attained a strong position across the country by serving our clients with wide spectrum of Gauge and Measuring Pins. Our range includes Thread Plug Gauge, Thread Ring Gauge, Plain Plug Gauge and Plain Ring Gauge.

Pressure Gauge

Pressure gauges and switches are among the most often used instruments in a plant. But because of their great numbers, attention to maintenance--and reliability--can be compromised. As a consequence, it is not uncommon in older plants to see many gauges and switches out of service. This is unfortunate because, if a plant is operated with a failed pressure switch, the safety of the plant may be compromised. Conversely, if a plant can operate safely while a gauge is defective, it shows that the gauge was not needed in the first place. Therefore, one goal of good process instrumentation design is to install fewer but more useful and more reliable pressure gauges and switches.

Diaphragm Pressure Gauge

Diaphragm pressure gauges measure gauge, absolute and differential pressure. In processing industries, they can be installed in applications with highly corrosive, viscous media. Diaphragm pressure gauges are ideal for these harsh conditions because the media can clog the narrow presure ports of threaded connections of Bourdon tube instruments as well as the internals of the tube. To prevent such clogging, diaphragm pressure gauges are connected to the process with an open flange. This configuration provides a large pressure chamber, which prohibts media from settling.

Diaphragm Pressure Gauge

- Measurement of low pressures.

- High overpressure safety.

- Use with critical media.

With liquid filled case for applications with high dynamic pressure pulsations or vibration Suitable in corrosive environments for gaseous, liquid or highly viscous media. Process industry: chemical/petrochemical, power stations, mining, on and offshore, environmental technology, mechanical engineering and plant construction

Differential Pressure Gauge

Differential pressure gauges are commonly found in industrial process systems, and theyŌĆÖre often a great solution for those settings, but unfortunately they tend to get overlooked or misunderstood. Knowing how differential pressure gauges work is as simple as knowing what differential pressure itself is.

Differential Pressure Gauge

- For gaseous and liquid aggressive media that are not highly viscous or crystallising, also in aggressive ambience

- Monitoring and control of pumps

- Filter monitoring

- Level measurement in closed tanks

Differential pressure measuring ranges from 0 ŌĆ” 16 mbar High working pressure (static pressure) up to 40 bar High overpressure safety up to 40 bar All welded media chamber Option: Low-temperature version down to an ambient temperature of -70 ┬░C (-94 ┬░F)

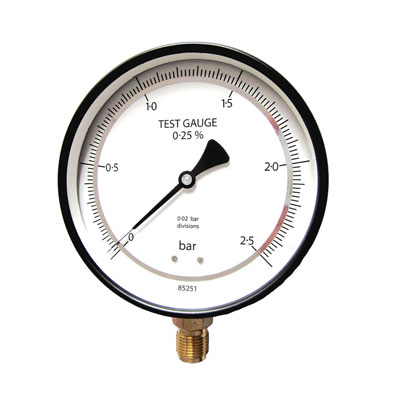

Master Pressure Gauge

Master Pressure Gauge is used to calibrate measurement instruments in ISO 9000 qualification laboratories. These calibration equipment offer an accuracy of ┬▒ 0.25%

Master Pressure Gauge

- Rugged stainless steel construction

- Protection IP65

- Usable to full scale

- Easy access for calibration

- High precision jewel bearing movement

Test benches, Calibration laboratories, Maintenance and repair shop, etc.

Sanitary Triclover Gauge

Sanitary Pressure Gauges are designed for applications with high hygiene requirements. They are constructed with Tri-clover sealed connections for measuring pressure in sanitary applications and are free of crevices and cavities to allow no areas for bacterial growth. Sanitary diaphragm pressure gauges are often found operating in Pharmaceutical, Biotechnology, Food, Beverages and Dairy applications.

Sanitary Triclover Gauge

Stainless steel, 316L, is compatable with most process medium, but could have a limited life when exposed to the aggressive cleaning solvents. Sanitary process technology mainly uses corrosion resistant austenitic stainless steels as standard materials. 316L is commonly specified in the American markets, within Europe 1.4404 and 1.4435 are both used. These materials are characterized by a d-ferrite content of < 0.5%. If this grade of stainless steel is not process or cleaning compatable, numerous other materials are available to extend the expected life cycle of the pressure measuring instrument┬Ā

Used typically in pharmaceutical, biotechnical, ultra-filtration, or food and dairy industries, these gauges can serve special applications involving chemicals, hard-to-handle liquids, and slurries. Gauges feature electropolished 316L stainless steel

Draft Gauge

Draft Gauges are used for low pressure measurement from ranges -25mmwc to 0 upto 6000mmwc.

Draft Gauge

A draft is defined as a velocity, but itŌĆÖs common to want to know the rate of air flow instead, so you can get these gauges with them scaled if a volumemetric scale like cubic feet.meters per minute. in that case the meter has a custom scale manufactured calculated from the cross sectional area of the ducting where the end user will install the gauge. Digital gauges can have this info inputted by the end user.

In the oil heating industry, ŌĆ£draftŌĆØ describes the vacuum, or suction, which exists inside most heating systems. The amount of vacuum is called draft intensity. Draft volume specifies the cubic feet of gas that a chimney can handle in a given time. Draft intensity is measured in ŌĆ£inches of waterŌĆØ. Just as a mercury barometer is used to measure atmospheric pressure in inches of mercury, a draft gauge is used to measure draft intensity (pressure) in inches of water. Natural Draft is thermal draft. It occurs when heated gases expand. A given volume of hot gas will weigh less than an equal volume of the same gas at a cool temperature. Since hot combustion gases weigh less per volume than room air or outdoor air, they tend to rise. The rising is contained and increased by enclosing the gases in a tall chimney. The vacuum is then created throughout this column of hot gases.

Temperature Gauge

A temperature gauge is a device used to indicate the temperature of an item being monitored. The display can be an analogue dial, an analogue range or a digital readout. Common methods of measuring temperature include bimetallic strip (the bending of which increases with temperature) and the thermocouple which produces an electronic voltage that depends on the temperature.

Temperature Gauge

- Simplicity in use and low cost.

- Portable Device

- Checking damage is easy

- Do not require any power

This instrument works best in applications such as power generation, oil and gas, waste water, and pulp and paper. Vapor Actuated Thermometers are economical temperature gauges that provide an accurate remote reading for applications such as refrigeration, solar heating, and water treatment.

Digital Temperature

Analog Temperature gauges have their advantages: They measure rate changes, can be viewed from long distances, and do not require power. But if accuracy is vital when measuring Temperature, industrial analog Temperature gauges simply cannot compare to how precisely digital Temperature gauges measure Temperature. Digital Temperature gauges offer many other advantages as well.

Digital Temperature

- No operator interpretation required

- No parallax error

- Back-lit capability

- Steady reading in high vibration

- Easy to re-range

This instrument works best in applications such as power generation, oil and gas, waste water, and pulp and paper. Vapor Actuated Thermometers are economical temperature gauges that provide an accurate remote reading for applications such as refrigeration, solar heating, and water treatment.

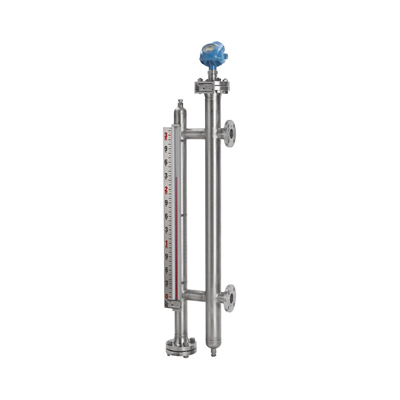

Level Gauges

Level gauges are meters used to determine the level of a liquid in a fixed storage or process tank. The gauge is composed of several parts including head, float, measuring tape, bottom anchored bracket, guide wires, elbows, anchors, coupling, pipe support brackets, and pipework. Liquid level gauge calibration is used to ensure proper readings are obtained when using level gauges.

Level gauges

- the use of mica shields or Polytrifluorochloroethylene shields to protect the glass from the corrosive action of the process fluid

- the observation of interface

- the observation of the liquid colour

Continuous level indication without power supply Indication of the level proportional to height Individual design and corrosion resistant materials make the products suitable for a broad range of applications Chemical, petrochemical industry, oil and natural gas extraction (on- and offshore), shipbuilding, machine building, power generating equipment, power plants Process water and drinking water treatment, food industry, pharmaceutical industry

Reflex Level Gauges

Reflex level gauges are designed to detect the difference in refractive indices of vapor and liquid and level detection and can be used in a number of process applications.

Reflex Level Gauges

- They do not need electrical power to operate. This can be a great advantage in the case of a power outage.

- Simple to install ŌĆō no calibration is necessary.

- Can be used as a reference to check, or calibrate, other level technologies.

- Pressure rating from vacuum to 4000psig.

- Temperature rating from -150oF to 750oF

- Not affected by the chemical or electrical properties of the process liquid. Specific gravity, dielectric, conductivity, surface turbulence, vapor, foam, etc. no longer needs to be considered.

when the separation level between two liquids has to be read (interface) when besides the level indication, the observation of the liquid colour is required when the process fluid is high-pressure water steam, since in this case the glass must be protected from the solvent action of the boiler water by using mica shields when the process fluid is such that can corrode the glass (e.g. high temperature alkaline solutions or hydrofluoric acid), since ica shields or Polytrifluorochloroethylene shields must be used to protect the glass

Tubular Level Gauges

Tubular Level Gauge is the simplest form of level indication. General Instruments Consortium offers economical and reliable level gauges for direct reading of level in tanks / vessels. Tubular Level Gauges are used to visualize the level in low or medium pressure application. Tubular Level Gauges are mounted on the side of the tank / vessel. It consists of Glass Tube, Packing Material, End Blocks and Isolation Valves, vent plug, drain valve etc.

Tubular Level Gauges

The most advantage of this type is for easy level reading of boiling liquids restricting in temperature application rating. When liquids are boiling, their bubbles make the surface level indistinct. The manual adjustment of isolation valve at the input of the media entering the chamber reduces the bubbling. Therefore the level gauge ease to read the level or bubbling liquids. It also provides advantages for highly dense and viscous liquids, as the body is made of seamless pipe. This level gauge is designed and manufactured for easy and accurate reading the liquid level of highly foamy liquids. The gauge has a relatively spacious internal area where foamy liquid is held from forming foams.

Level Measurement,Level

Float & Tape Level Gauges

One common form of level measuring system uses a tape or servo motor which is connected to a float. The height can be read as the float moves with liquid level. Float devices use the buoyancy of a float to indicate the liquid level in the tank. One common approach is to attach the float to a chain. The chain is attached to a counterweight which indicates the level as the float moves up and down. These types of device are often found on large atmospheric storage tanks.

Float & Tape Level Gauges

- Low cost, continuous measurement

- Models to suit the majority of modern atmospheric storage tank designs

- Digital readout ŌĆō metric or imperial

- Tank base or tank-top mounting

- Range of transmission options

Mechanical Float Gauge Water Float Gauge Oil Float Gauge

Transparent Level Gauges

In this kind of level gauge, the fluid is held between two smooth glasses. The level can be identified as the fluid has a different level of transparency compared to gases and steam. The transparent level gauge is particularly recommended for applications where the glass needs to be protected from corrosive fluids and high temperatures. A lamp can also be fitted behind the gauge to improve visibility in special operating conditions. The product line includes level gauges suitable for pressure ratings from PN10 to PN250 and a huge number of industrial process applications

Transparent Level Gauges

- Very simple

- Inexpensive

for use with corrosive fluids (protective shield for the glass is required) for steam with an operating pressure > 20 bar (protective shield for the glass is required) if repeated thermal shocks are likely (protective shield for the glass is required) for checking the interface (level of separation between two immiscible fluids) for checking the colour of a fluid. for dirty / oily fluids

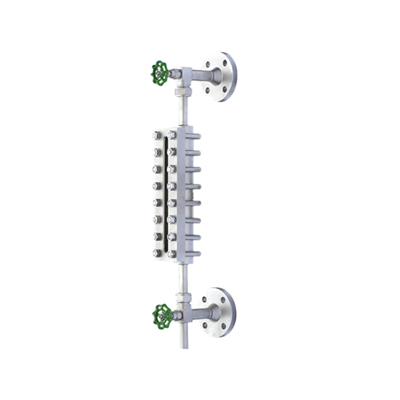

Magnetic Level Gauges

Magnetic level gauges work on the principle of communicating vessels, therefore the level in the measuring chamber will be the same as the level in the vessel. The measuring chamber is fitted with a float, which has a magnet inside. The float with magnet will float on the medium and the magnet in the float will turn the flaps of the indicating rail. The float in the measuring tube is standard not pressurized and has no magnetic or mechanical guidance. This construction makes the float less dangerous than a float which is standard pressurized. When necessary Hadro can produce a pressurized float.

Magnetic Level Gauges

- Standard unpressurised floatsystem

- Float without mechanical or magnetic guide rails

- Fully corrosion resistant system

- Measurement is unaffected by pressure, vacuum, temperature, foam and viscosity

- Minimum sensitivity to density variations

- Permanent indication without external power supply

- Low temperature version is fitted with ice free indication strip

- Fully adjustable switches

- Back lighting is unnecessary

- Eccentric drain cannot blocked by the float

Feedwater heaters Industrial boilers Oil/water separators Flash drums Surge tanks Gas chillers Deaerators Blowdown flash tanks Hot wells Vacuum tower bottoms Alkylation units Boiler drums Propane vessels Storage tanks

Float & Board Level Gauges

Float and Board is a simple economic level measuring instrument for large non pressurised storage tank. Its is a simple float and counter balancing mechanism, float inside the tank and counter weight (scale pointer) connected by the rope wire which is moving freely on the pulley assembly. When the storage tank is empty position, the float located inside the bottom of the scale pointer located at ZERO level on external scale. If the liquid level rie in the tank, the float move upper side and scale pointer move downward on the graduated scale to show liquid level inside the storage tank. If teh liquid level turbulance inside teh tank use float guid rope wire assembly with ANCHOR for stability of float.

Float & Board Level Gauges

- Simple

- Easy mounting

- Low maintenance

- Economical measurement solution

- Assured level indication without power supply

Chemical, petrochemical industry, Refineries Pharmaceutical industry Pressure vessels, Storage tanks Marine industry Water & waste water treatment plants etc

Sight Flow Indicators

A sight flow indicators is a device installed into a pipe to provide a visual of verifying liquid flow for direction and accurate flow rate. Sight flow indicators allow operators to observe the color and clarity of liquids through a window. A sight flow indicator is a body with one or more viewing windows, usually with gaskets, and a way to mount the indicator to the pipeline, such as flanged, threaded, or sanitary clamp connections. Sight flow indicators are available to fit standard pipe sizes ranging from 1/4-inch to 16-inches and carry ANSI pressure ratings. Sight flow indicators allow direct observation that do not give a false reading, lose power, or unable to read. Sight flow indicators may be applied to almost every phase of movement, whether it is liquid, gas or powder. Operators of the Sight flow indicator can see the approximate rate of flow, direction of flow, and condition without interrupting process flow. To find out more about the John C. Ernst sight flow indicators, contact one of our specialists today.